|

Brake Fluid

| Characteristics |

| Slightly hygroscopic |

| Resistant to aging |

| Neutral (metal, rubber) |

| High wet boiling point |

| Low pour point |

| Low compressibility |

| Constant compressibility |

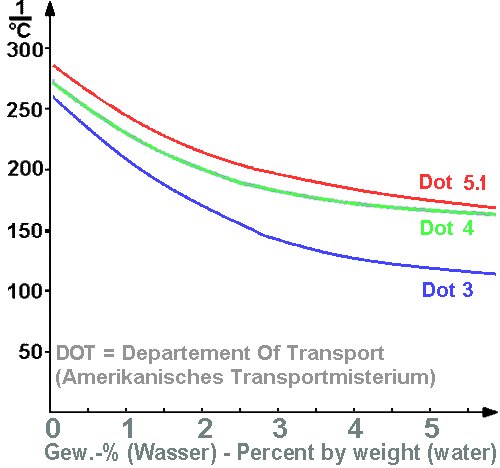

| The wet boiling point is measured at a 3,5% water-content. |

The brake fluid should, through a high (wet) boiling point, a low solidifying point and a constant viscosity, through a large range of temperature, transfer the pressure from the main brake cylinder to the wheel brake cylinders. Whereby, the regulation systems (e.g. ABS) must also still function at low temperatures. The solidifying point of brake fluid lies at below -65°C.

| Keep mineral oil away from the brake hydraulics! |

Brake fluid is made up of polyglycol compounds and sometimes also silicone fluid. In comparison with motor-oil there are considerable differences. The two substances may not be mixed with each other when

disposing of them. Due to the fact that the brakes can become hotter than the engine, the brake fluid must be particularly protected against the development of steam bubbles. Unfortunately, it is prone to

taking on

water (hygroscopic), which lowers it's wet boiling point and if it's not changed at adequate intervals, can possibly cause a complete braking system failure.

| Brake fluid is toxic and attacks the paintwork. |

Water primarily penetrates the hydraulic system through the brake hoses and the rubber gaiters when releasing the brakes. This is just one reason why the brake fluid must be regularly changed. At the same

time,

some of the abrasion debris from the seals is possibly rinsed out. Should one not be prepared to observe the regular replacement intervals, one can use a suitable tester to help ascertain the moisture content.

Water is also largely responsible for internal corrosion.

| The flexible tubes/piping should be replaced regularly. |

Brake pipes- and hoses mostly undergo an optical check-up. Of course, a long-time pressure test is also possible. The pipes can leave their mountings, they can chafe, be corroded and, particularly at their

connection points, be leaky. One can bend the flexible tubes to be able to better recognise surface cracks. When the springs are compressed and when steering, one must make sure that the tubes have no

contact

with foreign bodies. Not only are they susceptible to exterior damage, taking the increasing age of the vehicle and/or the amount of time that the vehicle has not been in use, they are prone to swelling, right up

to the

point where they are completely blocked.

| Brake-line checking is vital. |

Should you be of the opinion that check-ups are not all that important because, after all, there is a second brake-circuit available, then please, don't underestimate the shock you will get when you press the

brake

pedal, and nothing happens. You will forfeit several meters of braking distance which cannot be compensated for by the

function of only two wheel brakes, not to mention that the car will pull strongly to one side.

| Lowest permissable boiling point temperature in Germany: | | 180°C |

Unfortunately, the acceptance of the brake fluid change has suffered somewhat because vehicle owners felt that arbitrary and too frequent changes were being carried out. Ever since brake fluid can be tested,

these

problems can be considered as settled. The device shown above gives the boiling point of the brake fluid tested and thus, allows a clear picture of the state of the liquid. 04/13

| Brake fluid |

| Highly durable -> silicon based |

| Otherwise polyethylene und glycol (95 %) (95 %) |

| Not mixable with each other. |

| DOT 3 | 140°C | FMVSS 116 |

| DOT 4 | 155°C | FMVSS 116 |

| DOT 5 | 180°C | ISO 4925 |

| DOT 5.1 | 175°C | ATE |

| DOT 5.1 | 180°C | ISO 4925 |

|

|