|

(Electrical) Magnetism 4

Even in the era of ever increasing electronic control systems, the working current relay has well defended it's place in the automobile. It has the ability to switch high working current using only low control current. In

addition, it separates the working- from the controlling current much better than the transistor does. Short circuits in one do not affect the circuits of the other.

To reach a relatively high magnetic flow, a thin wire coated with lacquer is very tightly coiled around an iron core. Thereby, a relatively low current in the controlling circuit is sufficient to move the spring-loaded contact

(below on the right of the picture) to the left, thus closing the working circuit safely again. A relay can, in slightly altered construction form, switch 30 A and more, in the form of a magnetic

switch (solenoid), even more than 100 A. In the above picture, a closer-relay with 4 connections is shown. Opener/closer-relays have 4 connections, change-over-relays have 5 connections. Opener/closer-relays,

as the name indicates can, when power is applied to the terminals 85 and 86, only open or close a circuit.

One can check the

function of a relay by simply laying on the control current and waiting for a clicking sound. If a click can be heard, then the component is probably OK. To check the working component, one must connect a continuity

tester to the two free terminals at the same time. In the case of a closer-relay, it will chirp when the control current is laid on and with an opener-relay, when no current is laid on. In the case of the change-over-relay, 3

terminals are left over. Two of them always have contact, depending on the switch position.

If a power relay is switched off, the switch and the iron core remain in the working position. The spring brings them back into the starting position. Thereby, current peaks which can damage sensitive electronic

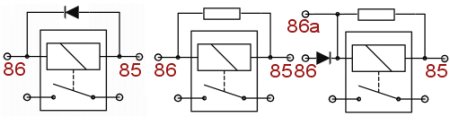

devices, can occur. For this reason, the magnetic coil is often given a resistance (picture, on the left) either that or a so-called catch-diode (picture, in the center) is switched parallel so that this is avoided. On the right

you can see another circuit with a reverse polarity protection.

In modern vehicles there are still several power relays in use. They offer an economic method of converting low current signals into those with a high current flow. Apart from that, the above mentioned galvanic

separation is an advantage. However, more and more transistor controlled relays are being installed, even more outside of the motor vehicle technology.

Although these are more expensive, they require only one fuse for the controlling current. Due to their substantially faster switching speed, they can, if necessary, do time-clocking and through a continuous checking of

the working current, switch off instantly. So, they are relays which are equipped to cope with occurring faults. Of course it is sometimes more difficult, to find the reason if they're not doing their job properly.

A power relay can be the reason why it may be difficult to localise a fault. There is, first of all, as in a number of printed circuits, the possibility of a cold soldering point, this may appear to be ok but does not connect

conductively, particularly in the power circuit, where higher currents and the resulting heating up are possible. Indeed, the Wolfram coating on the contacts may also be faulty which can cause them to be caked

together. Thus, in the case of a fault, a power relay can either be permanently open or permanently closed. 04/13

|

|