Two-stroke engine 2 Two-stroke engine 2

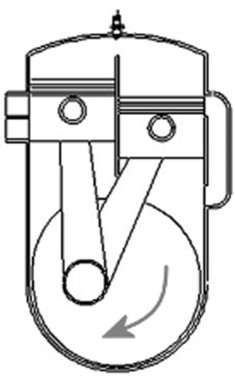

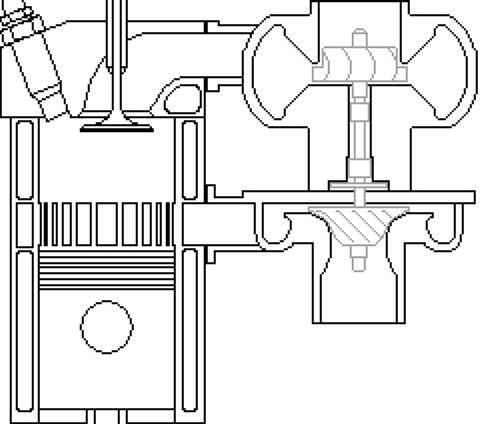

If you think that this marks the end of the race to improve engine scavenging, you are sorely mistaken. The rotary valve has been around for more than a hundred years. In the simplest case, access to the

crankcase is controlled not by the piston, but by one of the two crank cheeks (which are particularly large in two-stroke engines), or even by a channel through the crankshaft. Depending on the angle of

rotation, they expose an opening through which suction can be drawn.

kfz-tech.de/PVe67

Incidentally, a diaphragm can also be used as an opening to the crankcase; this could also be called an air no-return valve. It opens whenever a negative pressure is created in the crankcase, allowing fresh air

to flow in. A typical example is the horizontal engine of a lawnmower, with the cylinder on one side and the intake manifold with carburetor and air filter on the other.

Rotary valves for the intake are, of course, not as crucial for the scavenging process. They are more effective, for example, for the exhaust port (Yamaha). However, they require additional installation and must

be driven by the crankshaft. Here too, due to problems with heat, lubrication, and lacking sealing, rotary valve systems have not become widely used.

| By the way, such double-piston engines are considered to be single-cylinder engines.

|

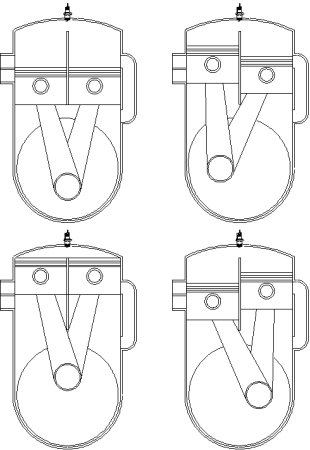

The direct current scavenging system seems to be more promising. Consider the possible movements of the two pistons, regardless of whether their piston rods run on a crankpin or are directly connected to

each other. The important thing to remember is that, from bottom dead center to top dead center, the left piston is higher, and from top dead center to bottom dead center, the right piston is higher. Therefore,

the exhaust port on the left side opens and closes earlier than the transfer port.

It is said that direct current scavenging has an asymmetrical control diagram. So, advantages can be expected from this side. Unfortunately, this is not the case when considering the oddly shaped

combustion chamber, which has drawbacks regarding rapid pressure build-up and exhaust gas development. Furthermore, a cylinder head that spans two cylinders is difficult to mount and is subjected to

unfavorable thermal stresses. Leaks can be a consequence of this.

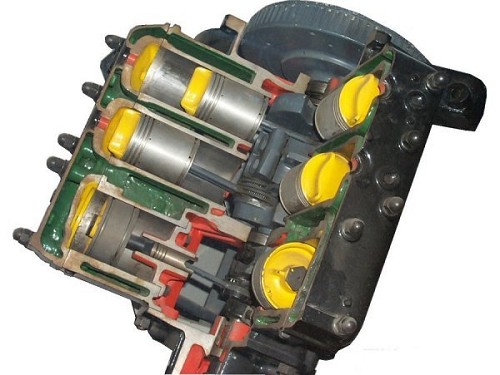

Finally, there remains the charger motor. In this system, the pressure is no longer generated by the underside of the pistons, but by two additional cylinders, where the necessary pressure is created above

and below the pistons. This system only works with an even number of active cylinders; in this case, only four at the bottom.

kfz-tech.de/PVe68

Now you might ask why the concept of supercharging is combined with the old-fashioned construct of cross-flow scavenging. This reveals a disadvantage of reverse scavenging, namely that it is absolutely

dependent on absolutely constant delivery through the two overflow channels. f one of the two delivers more, the central confluence at the rear wall and the uniform displacement of the old gases is jeopardized.

A word about lubrication. Since gas-tight crankcases for each cylinder are not necessary in this design, this engine could also operate with with an oil sump and pressure circulation lubrication. Normally, the

crankshaft and connecting rods use needle bearings to take advantage of the engine oil that is drawn in along with the air-fuel mixture.

It's all no use, DKW has suffered shipwreck with this engine. It was neither particularly fuel-efficient nor had a sufficiently long lifespan. It's all no use, DKW has suffered shipwreck with this engine. It was

neither particularly fuel-efficient nor had a sufficiently long lifespan.

kfz-tech.de/PVe71

This is truly the star of the modern era. Container ships account for approximately half of global freight transport. The vehicle's diesel engine struggles to match the efficiency of this 3000-ton engine. In recent

times, even these giant ocean liners have had to adapt to fuel-saving driving practices, as this is more economical than simply trying to reach their destination as quickly as possible.

One meter bore and two to three meters stroke are the basic dimensions of these 4-storey high structures (picture above). Their massive engine blocks are usually cast in one piece, after weeks of preparation

and using all available means. They develop 74,000 kW (100,000 hp) at speeds around 100 rpm. A gearbox would likely not withstand that torque, and it would also take up valuable cargo space.

The crankshaft is directly connected to the ship's screw. To brake, reverse gear must be engaged. To do this, the engine is stopped and then restarted in reverse using the stored compressed air. While you're

thinking about it, you might also consider which engines would theoretically start if you put the vehicle in reverse gear instead of second gear when giving it a push to start.

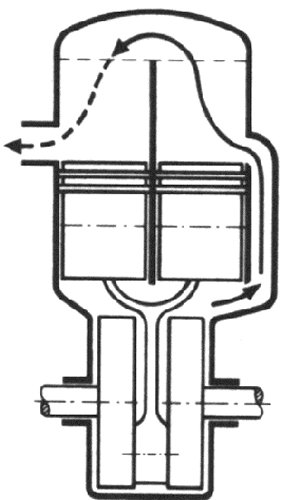

What happens inside the engine? Whenever the piston reaches a certain point before reaching bottom dead center, intake slits in the cylinder walls open. Air is blown in through these by powerful

turbochargers, which expels waste gases through valves that simultaneously open in the cylinder head. After the valves and slits are closed, fuel is injected into the compressed air.

Large engines have an oil sump, which is regularly drained. The amount of engine oil can be in the double-digit ton range. A complete oil change almost never occurs. Only partial quantities of the oil are

replaced, based on analysis of samples taken from the oil.

This fuel is a heavy oil distillate, produced and sold at low cost as a byproduct of refineries. It needs to be heated significantly before it can even be used in a ship's engine. Its use is now prohibited in an

increasing number of ports and entire shipping lanes, such as the North Sea. Here, expensive diesel fuel must be used.

|