Two-stroke engine 1 Two-stroke engine 1

kfz-tech.de/PVe66

A two-stroke racing machine with 50 cm3, for example, would only laugh about the top speed of a four-stroke engine, even of an F1 engine. It can easily reach several thousand

RPM higher. If it has two in-line cylinders, it's even more superior to the four-stroke engine. This is because the opposing movements of the pistons allow for better mass balancing, whereas in

a four-stroke engine, the pistons move like those in a single-cylinder engine (see chapter two-cylinder).

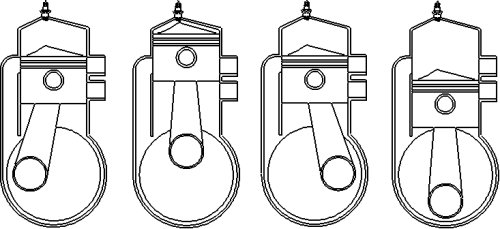

Yes, the two-stroke engine is called that because each cylinder has one power stroke during every two crankshaft revolutions. A "stroke" here refers to half a rotation of the crankshaft. Two

cylinders are sufficient to ensure that there is always a power stroke occurring. For engines with a small number of cylinders, the two-stroke engine has a significant advantage.

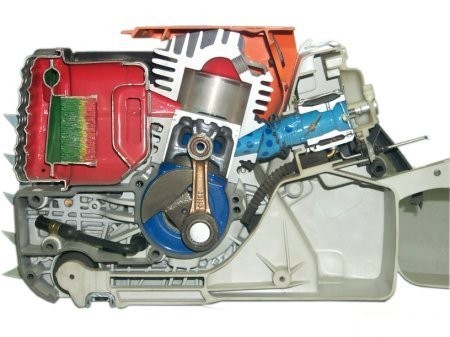

At the very top, you can see it as a small, air-cooled single-cylinder engine in a chainsaw. Combustion air is drawn in from the upper right, regulated by a throttle valve. In front of it is the

starter flap for enriching the engine during cold starts. The diaphragm carburetor draws fuel from the large tank on the lower right. It's a diaphragm carburetor because it can operate reliably

regardless of the chainsaw's position. The diaphragm below the throttle valve also serves as a fuel pump. The fuel line is particularly noticeable. To the left of the engine itself is the sound

absorption, possibly also with a small catalytic converter.

kfz-tech.de/PVe69

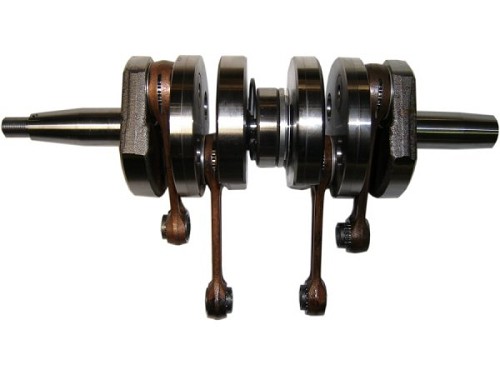

Generally speaking, the two-stroke engine only had up to three cylinders in line. More cylinders are possible, as shown by the conglomerated Hirth crankshaft illustrated above. With the

current trend towards downsizing, the two-stroke engine might get another chance, as manufacturers are finding it difficult to move beyond the three-cylinder configuration.

The question is whether the effort required to make a two-cylinder inline engine run smoothly is greater than the benefit gained by eliminating the third cylinder. On the other hand,

turbocharging makes engines so powerful that two cylinders are often sufficient for many vehicles.

Unfortunately, the two-stroke engine has damaged its own reputation. Anyone who has ever walked through the haze of two-stroke oil mixture in the real existing GDR will have formed a

judgment that will never be revised again. However, two-stroke turbocharged engines do not have to contain unburned fuel or engine oil in their exhaust.

Well, the initial attempts after the war using trucks (Krupp) can be considered failures. But who doesn't know about container ships, which transport goods around the world with an efficiency of

almost 50 percent? The cost of fuel for transporting goods from the Middle East to, for example, Rotterdam, was once as low as 0.02 euros per liter.

How does that work? First, we need to dispel the myth that two-stroke engines inherently don't have valves. This is currently true because they are only used in road vehicles for motorcycles

up to 125 cm3. However, if they were to be used again in four-wheeled vehicles, they would likely have exhaust valves and an oil sump similar to that of a four-stroke engine.

The intake valves would be replaced by openings at the bottom of the cylinder, which the piston would release when it had traveled a certain distance after BDC. Now imagine a turbocharger

forcing a massive flow of air through the cylinders while the exhaust valves are also open. If one didn't consciously want to contain exhaust fumes, one would be able to blow them all out.

The exhaust valves would have to close while the intake slots would still be free. From that point on, the turbocharger can create a kind of pre-compression. The rest is handled by the piston

once it has moved past the intake slots. How much compression is generated depends on the working process. In a diesel engine, a higher compression ratio is acceptable, and fuel is injected

shortly before top dead center.

But a gasoline engine with slightly lower end-of-compression pressure would also be conceivable. It could even start (partial) injections as soon as the exhaust valves are closed. This would

give it more time for fuel-air mixture preparation. Combustion would then be initiated, as usual, by an electric ignition.

Why haven't car manufacturers been working on this already? Firstly, we don't actually know if they haven't been working on it. Secondly, no technology is without its problems. For example,

there is the heat load on the two-stroke engine, which has been problematic even in the past. It has twice as many power strokes, which generate heat, and this puts additional strain on the

piston, cylinder, and in gasoline engines, also on the spark plugs.

At the same time, such an engine would go against the current trend towards being able to control every possible parameter. Intake ports that end as slots at the cylinder wall are less suitable

for such trends than intake valves, where timing and stroke can now even be adjusted independently of each other. After all, it's difficult to adjust the position of the slits while the engine is

running. Something similar existed a hundred years ago (the Knight principle), but it didn't prove successful.

And of course, in the field of four-stroke engines, one has not only a wealth of experience but also a lot of data at disposal. A two-stroke engine would therefore represent somewhat uncharted

territory, and would likely require at least 10 years of development time to reach production readiness. And what if it then fails to gain customer acceptance simply because it's a two-stroke

engine. Perhaps the 'Trabi haters' will have to die out first.

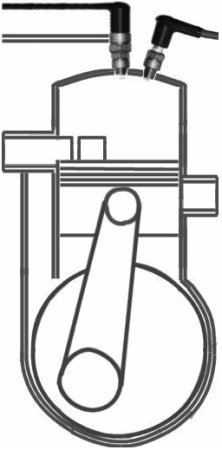

The main characteristics of a classic two-stroke engine are the control of the intake and, usually, the exhaust ports by means of slots in the cylinder, and the completely sealed crankcase for

each cylinder, often combined with a large crankshaft that fills almost the entire available space. As the piston approaches top dead center, it uncovers the intake ports and simultaneously

creates further negative pressure, drawing the air-fuel-oil mixture from the carburetor into the crankcase.

As the piston moves back towards bottom dead center, it closes the intake slots and simultaneously opens the transfer and exhaust ports. This allows the increasingly pressurized fuel-air

mixture to enter the combustion chamber. This process is facilitated by the suction effect of the exhaust gases that left the combustion chamber at the end of the previous power stroke.

Of course, it would be ideal if fresh and exhaust gases did not mix under most operating conditions, and if no unburned fuel could escape by closing the exhaust port at the right time. However,

this ideal has never been achieved with a simple two-stroke engine. As long as no special control mechanisms are installed in the intake and/or exhaust ports, the arrangement and size of the

slots can only be a compromise.

Incidentally, the possibility of supercharging on the underside of the piston was also considered very early on in four-stroke engines, but was never able to achieve any decisive success. Let's

stay with the two-stroke engine, specifically its timing diagram. A disadvantage of this design is its symmetrical nature. This means that the exhaust slots cannot be closed first on the piston

path to BDC and the overflow or scavenging slots to TDC later. The former usually stay open much longer. Nevertheless, even the pressure in the upper combustion chamber can still be

higher than that in the crankcase when the overflow slots are opened.

In the history of two-stroke development, attempts have sometimes been made to simulate the flow conditions in the combustion chamber using colored fluids, an indication of how much the

flow plays a role in scavenging. In principle, the path for the fresh gas to the outlet slit should be made as long as possible, for example, by keeping the pressure difference between the

exhaust gas and fresh gas relatively low. Mixing of the gases is also avoided by using a relatively small volume of fresh gas.

From this, you can see that the classic two-stroke engine, whether with a carburetor or external fuel injection, is generally better suited for smaller engine sizes. This, of course, does not apply

to the world's largest diesel engines used in container ships, where the use of exhaust valves and clean air for scavenging ensures that no fuel is present in the exhaust gases. This is where

the particularly favorable power-to-weight ratio of the two-stroke engine comes into its own.

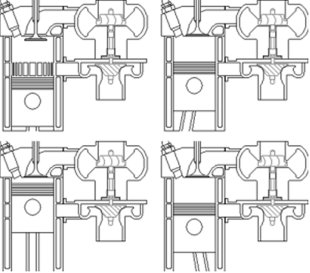

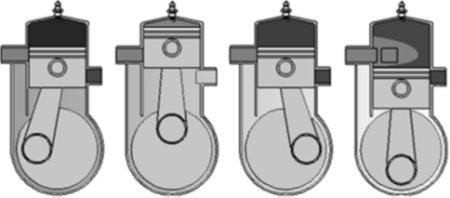

When dealing with a classic two-stroke engine, the scavenging process is particularly important. For a long time, cross-flow flushing with overflow and outlet slots on different sides was used here (image above). To

prevent the fresh gases from escaping directly, the so-called 'nose piston' was developed, with a particularly high piston crown in front of the outlet slot.

From a thermal point of view, a piston with a very different mass distribution is absurd and, given the resulting forces, is not very popular either. The cross-flow or three-flow flushing could not bring any improvement in

flushing, at least in the most frequently used load range, until Adolf Schnürle finally received the necessary attention for his reverse flushing. From 1932 onwards, this system was used by major manufacturers such as

DKW.

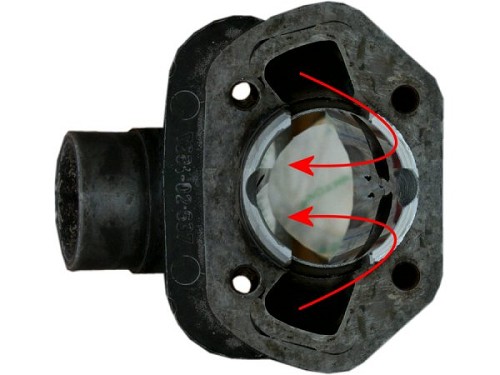

The exhaust is flanked on the right and left by two overflow channels, which hopefully guide the air-fuel mixture from the crankcase into the combustion chamber in a completely uniform manner. The gas flows meet on the

opposite side, where they rise partially into the head area and displace the old gases reasonably effectively (picture below). The long path from the inlet to the combustion chamber to the outlet is also clear here.

kfz-tech.de/PVe70

|