Combustion 4 Combustion 4

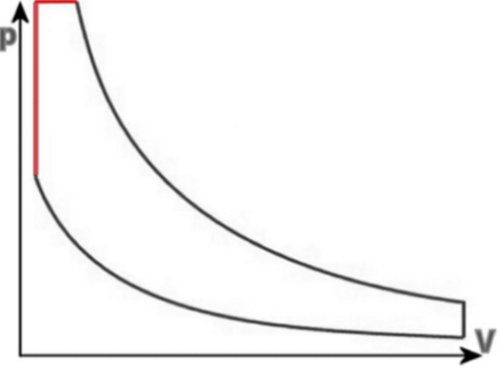

| Seiliger cycle (approximation to diesel engine) |

Actually, it is sufficient to reveal just a few key points about the first part of ignition, which lasts slightly longer than a thousandth of a second. The aim is to form so-called free radicals during the splitting of the molecular

chains via intermediate products. As the name already suggests, these are highly reactive and capable not only of initiating the actual chain reaction, but also of intensifying it significantly.

Typical for such a chain reaction is the formation of further free radicals through the separation of even slow-reacting molecules. If these reactions spread relatively evenly in all directions from the 5000°C hot arc of the

spark plug, you can imagine how important it is for the spark plug to be positioned relatively centrally. The prerequisite is, of course, a reasonably even distribution of hydrocarbon molecules.

Turbulence is therefore caused not only by swirling during intake, but also by the spread of the flame front. As mentioned, it is the shorter portion of the total approximately 2 milliseconds from

ignition to pressure increase. The more evenly the hydrocarbons are distributed and the more seamlessly they are lined up, the steeper the pressure curve. Slight enrichment of the mixture below lambda=1 is helpful here.

Conversely, a certain amount of thinning would slow down the process somewhat, while more severe thinning would even lead to disruptions. It would be helpful if you could consider at this point that with leaner

measures, it would be best to start the ignition a little earlier. This is because the pressure is most effective immediately after OT.

The ignition timing is too early if it already hinders the movement of the piston to TDC. As a rule, the slightly larger portion of the 2-millisecond combustion, which does not yet produce a pressure increase, will be placed in

the compression stroke. This results in an ignition timing of at least 36° (= 1 ms) before TDC at 6,000 rpm.

It is interesting to note that the combustion period is always approximately the same length, regardless of the engine speed. This means shifting the ignition timing depending on the engine speed. Now you know

where, for example, the 6° ignition timing at 1,000 rpm comes from, or the just under 5° at idle speed. It is always about one millisecond.

In the past, the control system was still mechanical. When the engine was stopped, it was possible to move the distributor finger slightly in the direction of rotation against spring forces. When released, it returned to its

starting position. This moved the flyweights on the lower part of the distributor shaft outwards. The two increasing engine speeds did this automatically, causing early adjustment.

Some gasoline engines were satisfied with this regulation, even though there is still a contrary requirement for ignition. It is the load-dependent adjustment that causes a late adjustment of the ignition. This is necessary

because a greater load, e.g., opening the throttle valve, supplies more air-fuel mixture to the engine through de-throttling.

Applied to the process already described, a denser structure of the hydrocarbons leads to faster combustion. That would bestow the piston already excessively high pressure even during the compression stroke. So a

reduction in ignition is necessary here. This is achieved by turning the plate on which the breaker contacts are mounted in the opposite direction to the rotation of the distributor shaft.

|