Gear shift Gear shift

kfz-tech.de/GtP1

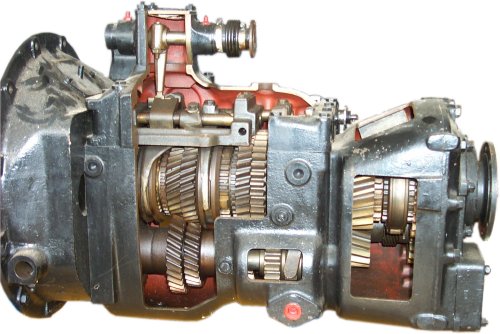

Undoubtedly, this transmission only reflects the current state of the art to a limited extent. It's a bit old-fashioned, but it's a good way to show us how the gear shift works. This refers to the small structure at

the top left. Please disregard the presumably extremely heavy cast iron housing. One can only guess at how many kilograms the mass would be reduced by using a modern aluminum housing, and even more

so with the addition of magnesium.

And please overlook the many grease nipples and praise the progress that these no longer need to be provided with new grease in such a gearbox when installed. So, the flanged part up there. This naturally

includes a standard drive system that was common at the time, with the engine relatively far forward and the gear stick somewhat further back.

This time, it does not intervene directly in the gearbox, but is connected to the flange at the top on the right via a solid rod. The forward and backward movement is transferred directly to the bar, although all

movements are reversed. If this is slightly twisted by the gear shift, the shift rod can be changed. This creates the H-pattern with the level 1st/2nd gear at the very back.

As you can see, you have to think the other way around here. That's why we repeated the pattern of the first gear again. With the engine on the left, the shift lever must be moved toward us and to the left so

that the corresponding shift rod is pushed all the way to the rear and to the right.

And what else is interesting about the transmission at the top? You can see how the individual shift rods are connected to the shift collars, and also why these have circumferential grooves. On the left, the two

gears that connect the drive shaft to the lay shaft are concealed. In the center, you can clearly see the straight-toothed reverse gear with the small gear wheel for reversing the direction of rotation, which is

inserted by a smaller shift fork, also from a shift rod at the top via an intermediate lever.

kfz-tech.de/GtP2

On the far right, almost at the exit, one can assume there is a separately switchable off-road mode. However, it cannot be ruled out that this is a so-called overdrive. This, mainly common in Great Britain, used

to help reduce the speed of the mostly long-stroke engines on the highway. If you look closely (and zoom in), you can even see the drive for the speedometer cable.

kfz-tech.de/GtP3

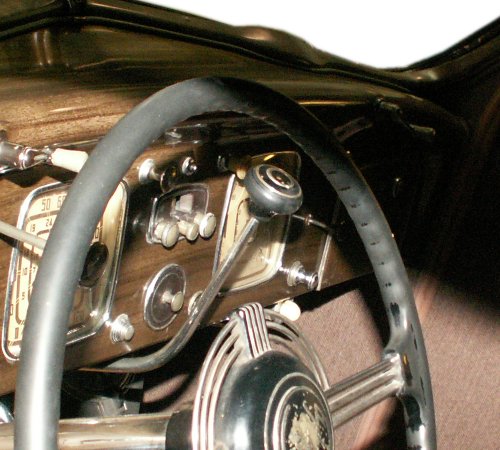

Take a look at this picture of a 1936 Chrysler Airflow. No, we don't want to focus on its aerodynamic bodywork, which was very famous at the time, but simply look at the gear lever. It is guaranteed to go

straight into the transmission, but the disadvantage is that it is located very far forward. Can you imagine that here you had to push the lever down rather than pull it toward you when shifting into second gear?

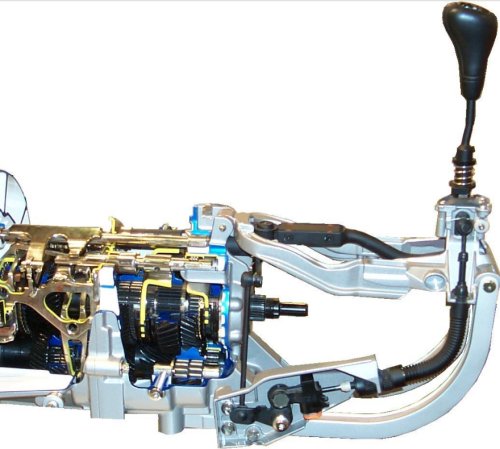

Here, it is already much more modern. You can see it on the gear lever. The rod transmits the forward/backward movement and the small Bowden cable transmits the rotation via three levers, one of which is

directly on the gearshift lever. You may have noticed that we are still dealing with the gear shift of longitudinally arranged transmissions.

The method shown has now become the most commonly used method for shifting a transversely mounted transmission. Previously, this was achieved using linkages and various deflections. For a long time,

Bowden cables could not hold a candle to them in terms of precision. But of course, each linkage had to be adjusted to the slightly changed position of the transmission.

You can save yourself the trouble here, if only the trains are long enough. The problem with a Bowden cable is not so much pulling as pushing. If you were to use them here just for pulling, you would need four

of them and an even more difficult adjustment. You can see from the spring on the shift lever that the special safety device for reverse gear is also installed here.

kfz-tech.de/GtP4

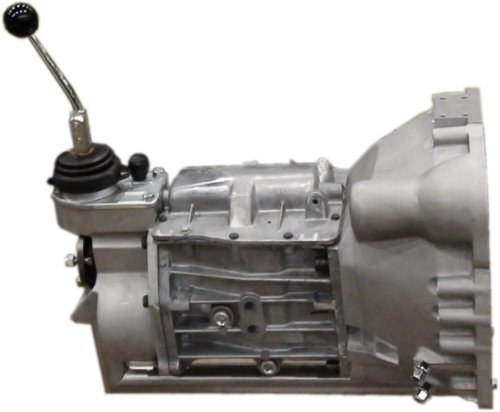

Finally, we need to use your imagination a little more. We are now on the top of the transmission. Ignore the toothed wheels inside and concentrate on the four flat metal plates stacked closely on top of each

other. These are now our shift rods, because they don't necessarily have to be round. The advantage here is that the distance from one shift rod to the next is pleasantly short.

Now imagine a shaft guided from above into this opening with an extension that is as narrow as flat metal. The Bowden cable for the left/right movement of the shift lever guides it more or less into this opening,

and the other causes a rotation that moves the straight flush flat metal to the left or right. At the very bottom, there is another guide for the shaft, as precision and minimal play are very important here.

kfz-tech.de/GtP6

| Classic, longitudinally mounted transmission with short rod transmission |

|