Shifting claw transmission Shifting claw transmission

kfz-tech.de/PGt32

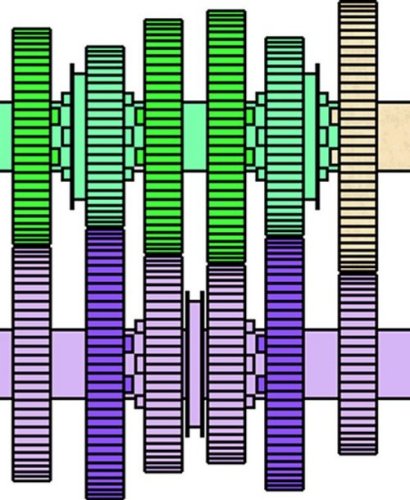

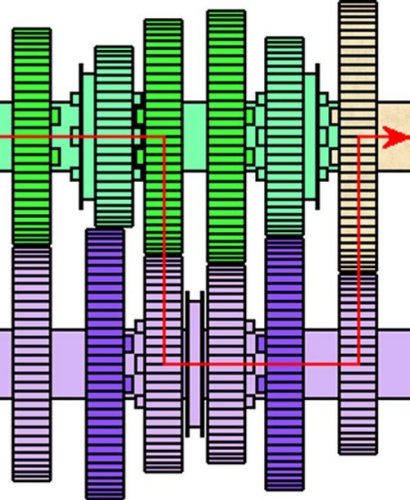

First, let's take a look at the basic structure of this transmission. As many toothed wheels on each shaft as the transmission has gears, all straight-toothed. However, this is only necessary for the inner four

because they are shifted against each other even though they still mesh with each other. In principle, the outer ones could also be helical, because they are firmly connected to the shafts and therefore cannot

be moved sideways.

kfz-tech.de/PGt33

But wait, of course there are not just two shafts here; the upper one is divided into a long left-hand section connected in various ways to the left-hand five toothed wheels and a right-hand section connected to

the remaining ones. The second and fifth toothed wheel from the right are fixed to the shaft but can be moved in longitudinal grooves, as can the interconnected toothed wheels three and four below. All the others

except for the four are therefore fixed wheels.

kfz-tech.de/PGt34

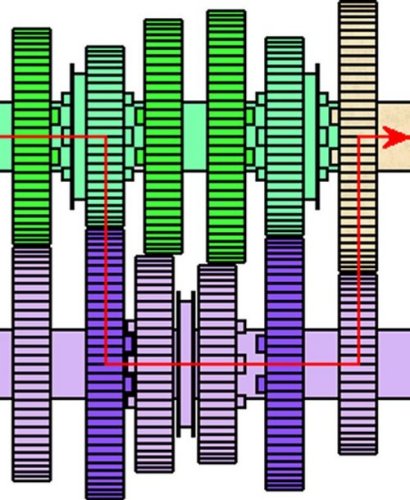

The axially movable wheels can also be recognized by their circumferential grooves, into which shift forks grip. This results in six shifting options for the individual gears, apart from their middle positions. The

shift sleeve at the bottom engages first gear when pushed to the left and second gear when pushed to the right. The fact that the wheels do not mesh completely with each other is unimportant because the power flow runs

via other wheels.

kfz-tech.de/PGt35

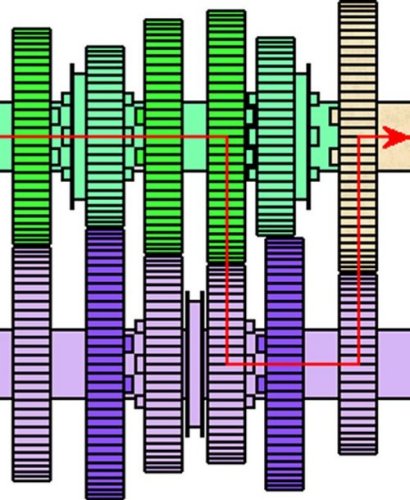

The left-hand idler gear at the top is responsible for third gear when in the left position and fourth gear when in the right position. This shows that in this function it does not act as a toothed wheel, but rather as

a shift sleeve. This dual function of the wheels is the reason for the incredible compactness of this six-speed transmission.

kfz-tech.de/PGt36

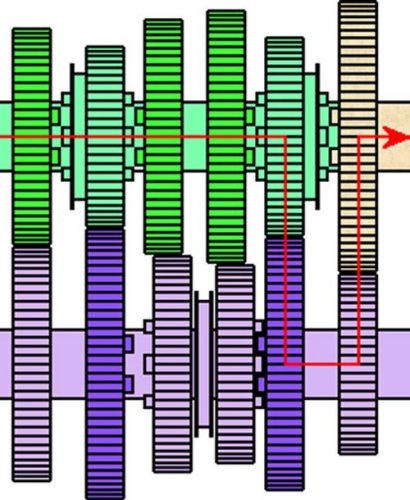

Still remains the idle gear at the top, which engages fifth gear when in the left position and sixth gear when in the right position. Somehow, the output shaft must also be secured in the drive shaft beneath it.

And then there is an additional boring through both shafts for the rod to operate the clutch. If not for weight savings, the lower shaft could be designed to be solid.

kfz-tech.de/PGt37

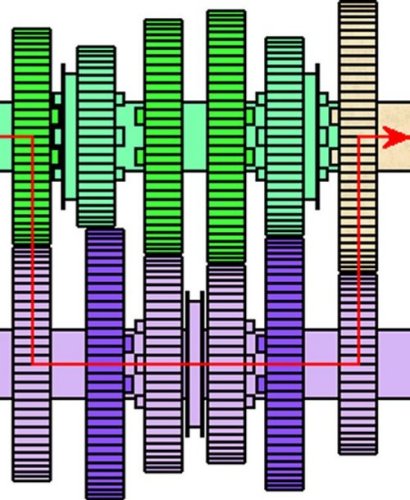

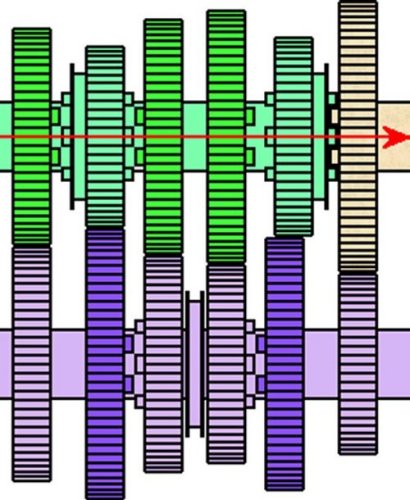

No, there is no H-pattern gear lever here. Instead, a shift shaft visible in the image below is used. This has a groove for each shift fork, which is shaped in such a way that, with a respective, precisely defined

partial rotation, it engages gears 2 to 6 in sequence, for example, and at the same time disengages the gear before it. These partial turns are possible by means of a lever that the driver pulls all the way up with their foot

once at a time.

It should now be clear that the lever must be pressed down a total of four times from sixth to second. Strangely enough, however, the second is followed by idling and then the first. This is achieved from neutral

by moving the foot lever downwards, and the other gears from there via neutral by moving the foot lever upwards.

kfz-tech.de/PGt38

The question remains as to why there is always a clicking sound when first gear is engaged in this transmission. This is due to the clutch, which, even when engaged, slightly drives the transmission gears,

which are then forcibly braked when first gear is engaged. The noise is exacerbated because the connecting claws do not fit exactly into the respective gaps, but rather there is a lot of space between them.

kfz-tech.de/YGt12

|