Exhaust pipes Exhaust pipes

Don't you find it strange starting a chapter on exhaust pipes with a vehicle that doesn't have any. So do we, but if you want to explain something, it is sometimes good to describe the starting point. Which already answers the

question of whether an engine runs at all without exhaust pipes. Of course, the Blitzen Benz from 1909 shown above was even the fastest of its time, admittedly not because of the missing pipes, but because of its

displacement of well over 20 liters.

In the history of the internal combustion engine, it has not happened infrequently that it was started without an exhaust system. E.g. if it had been removed and repaired and you wanted to know whether the installation would

be worthwhile at all. The induction pipe of the fuel pump was quickly plugged into a full canister and a battery connected. Then either the starter or, earlier, the crank could be used to start the engine.

If the resistances were not so great, a rope wound around the front V-belt pulley helped sometimes. Flames sometimes came out of the cylinder head's exhaust gas ports. It was good if the canister was placed on the other

side. But many repairers weren't interested in that, the main thing was that it ran, even if it was only briefly brought to life by the start pilot. The intricacies of the fuel supply were taken care of later.

But in none of these tortures an engine has ever sounded in my opinion as loud as that of the formula car shown above, derived from the DKW F1 from 1931. That little two-stroke engines can be so loud. Because they

actually need a skilfully scaled-down exhaust so that backlog can develop and a reasonably large compression. But the had enough power within the scope of his possibilities and roared them out too.

No, we do not want to deal with sound attenuation in this chapter. It's about pipes, with the rear engine only short ones, with the front engine with side outlet longer ones and the longest to the rear. They should be smooth

and, despite soundproofing, bring the exhaust gas outside as quickly as possible at a suitable location. Amazing how small the diameters of the ends can be. Just look at a two-wheeler.

For a long time at the beginning the VW Transporter had a thinner tube than the Beetle two of which, although it had the same performance. How is that to be explained? Perhaps with torque, which the transporter needed

more and which was also documented by a larger flywheel. Torque doesn't need such huge diameters. However, often also not as much power as the exhaust-pipe ends suggest.

| Torque usually arises at lower speeds than performance. |

Since we're at the Beetle now. It was so compact that it could often even be started with complete exhaust system. Because its cooling did not take up much space either, it was not infrequently used as an industrial motor or

auxiliary drive system , e.g. in sweeping machines to drive the rotary broom. However, the short distance became a problem due to the many measures for exhaust gas detoxification and noise insulation. A good example is

the current Porsche 911.

Yes, for a long time the elegant guidance of the fresh gases had been taken care of intensively and hardly that of the exhaust gases. Often there was not enough money for that. Which customer of a small Fiat with a rear

engine would have taken care of the exhaust system, unless it had to be replaced inexpensively in the event of repairs. Someone like Carlo Abarth did. Here he found grateful sacrifices in the form of obstructing diameters

and pipe guides. It is said that already here alone he would often have found a 10 percent and more increase in performance.

It may not sound like much, but just through other pipes? No, simply routing the outlets of multi-cylinders into the open air like the one at the top is certainly not the best way to generate performance. Why? Because the

cylinders can help each other. Because the exhaust pipe of every single one is not always filled to the brim, just during the exhaust stroke. In between there are quite a few transport gaps, which can also act as a negative

pressure or cause of vibrations.

If the cylinders are filled with naturally different outlet times, this helps both flows. But, but that's when the dispute starts. The dreaded representatives of the 4-in-1 faction appear and declare that this is the only way to get a

four-cylinder up to speed. The friends of the y-pipes argue against this. First two for the cylinders 1 respectively 4 and 2 respectively 3 they would like to know used. Then, after a well-defined distance, the two remaining

strands are brought together. Who is right?

We'll see each other again at the engine test bench and once the one group will probably be hit and then the other. That also depends on the requirements of the respective engine. Maybe 4-in-1 guarantees higher

performance and 4-in-2-in-1 more torque. In addition, there are a number of special features of this particular engine, such as the effective (not necessarily geometric) compression and of course the valve timing.

As you can see on this Benelli 750 Sei, there have also been constructions that have relinquished with both of the options described above. Rest assured, there are three more tailpipes on the other side. Or did one

consciously want to point out the six cylinders? After all, in the following 900 series, the three pipes were again combined into one at the end.

So obviously the impression that the exhaust system makes with the number of its endings plays a major role. It used to be clear that each tailpipe had a separate connection to the engine. Of these, one is already very far

away. It's not even clear now whether an end piece is connected to the exhaust system. Meanwhile the testers are checking this, half lying under the car.

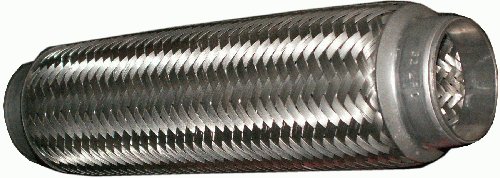

| Flexible intermediate part |

It is problematic in general to give the exhaust pipe little room to move. Some manufacturers of front-wheel drives with transverse engines experienced this with great problems. If the engine was not mounted in a relatively

stable manner without the possibility of movement, then the relatively flexible connection from the engine compartment to the rest of the system was overloaded and broke. Here, too, the result was a lot of noise.

In order to get you again a little more enthusiastic about exhaust systems, here is a look at the work of the professionals from Formula 1. Unnecessarily long pipes starting on the left, which get shorter and shorter to the right

so that they are the same length for all cylinders and the exhaust gas back pressure does not differ.

|